Supercritical CO2 (sCO2) for Heat Removal

What is the sCO2-based heat removal concept?

The sCO2-HeRo system is an innovative heat removal concept that has the potential to improve the safety of both currently operating and future Nuclear Power Plants (NPP) in Europe. The system is independent of NPP type and can be easily retrofitted to existing reactors. There is to date no such heat removal system with sCO2 as working fluid applied in the nuclear industry today, despite ongoing research on sCO2-power cycles as the main system in generation IV reactors. Based on this system, sCO2-4-NPP will develop a scaled-up sCO2-based heat removal system using real NPP dimensions and specifications for integration and validation in a real NPP (KONVOI PWR type). The sCO2-4-NPP technology will be implemented as an independent complement to the existing water-based systems and will have a very compact design, which will not require any major modifications to the existing NPP infrastructure.

The sCO2-4-NPP system will safely remove heat from the reactor core through the use of several highly compact, self-propellant, self-sustaining, and self-launching cooling system modules where each module is powered by an integrated Brayton cycle (also called the Joule cycle) using sCO2 as its working fluid. At the time of an accident, all the sCO2-4-NPP system modules will be turned on for a maximum nominal power to remove decay heat. As decay heat, after reactor shutdown, decreases monotonically in the days following the accident, the need for heat removal decreases accordingly and hence one module after the other is turned off.

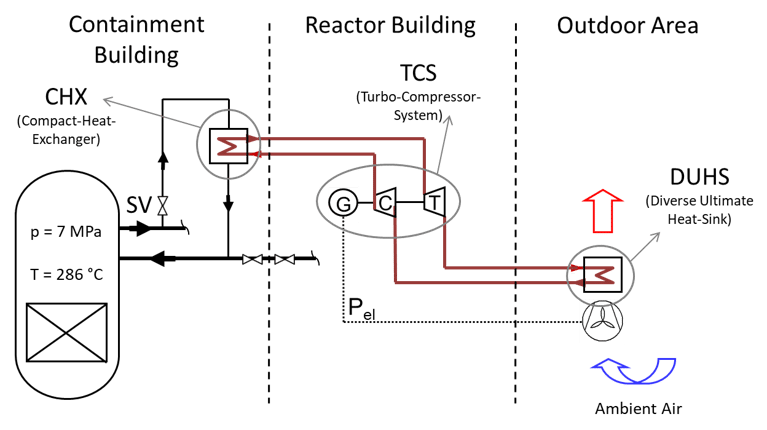

In general, a simple Brayton cycle consists of a heat exchanger (CHX) to the heat source, a turbo-compressor system (TCS) consisting of a turbine, compressor and generator, and a heat exchanger to the diverse ultimate heat sink (DUHS). The sketch shows one Brayton cycle attached to a Boiling Water Reactor. In case of accident, the containment isolation valves will close and the safety valves (SV) will open. The steam from the generator will flow into the CHX, which must be compact in size to fit into the limited space available in existing reactor containments. Inside the CHX the CO2 is heated up. The sCO2 then flows through the turbine (T) which is located on the same shaft as the compressor (C) and generator (G). Downstream of the turbine, the sCO2 is cooled by means of air and is delivered to the compressor and back to the CHX.

Figure: Schematic sketch of sCO2-HeRo system attached to a BWR. The red lines correspond to the sCO2 circuit. (Source: Venker, “Development and Validation of Models for Simulation of Supercritical Carbon Dioxide Brayton Cycle and Application to Self-Propelling Heat Removal Systems in Boiling Water Reactors”, University of Stuttgart, IKE2-156, ISSN 0173-6892 (2015).)

The Brayton cycle fulfils the safety goal of removing decay heat from the core to the diverse ultimate heat sink (air) while simultaneously producing electricity. Over a large operating range, the turbine of the Brayton cycle provides more power than the compressor needs to operate; the excess power is converted into electricity. This means that the sCO2-4-NPP system modules are independent from internal or external power supply raising nuclear safety to a new level. In addition, the excess electricity that is produced can be used to power additional fans for better heat removal to air or to power other systems, like batteries.

As the sCO2-4-NPP modules deliver the heat to air, safe decay heat removal is accomplished without the need for external water contributing to an increased level of safety.

The sCO2-4-NPP modules shall operate with almost no operator action (design goal). They shall start upon automated signals, e.g. magnetic valves, operate self-propellant and be self-regulating. Achieving these operational targets, the sCO2-4-NPP system will reduce active operator interventions in case of accidents and thus reduce the probability of human error.

Due to the similar steam parameters of a BWR and the steam generator of a Pressurised Water Reactor (PWR), from the thermodynamic point of view, this system can be attached to both existing PWRs and BWRs, thus addressing the majority of Light Water Reactors in Europe.