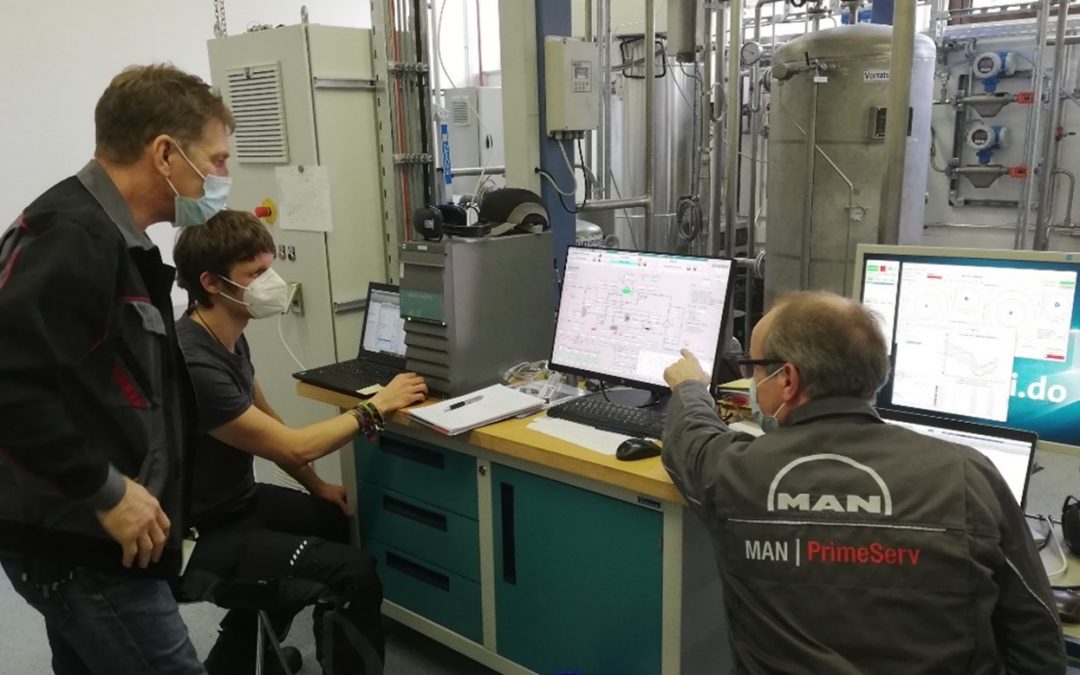

Figure: Commissioning of new turbomachine with magnetic bearings in the sCO2-HeRo cycle by partners UDE (Alexander Hacks, middle), KSG/GfS (Thomas Freutel, left) and subcontractor MECOS AG (Beat Aeschlimann, right)

In the sCO2-4-NPP project, partner University of Duisburg-Essen (UDE), in consultation with Baker Hughes, develops the turbomachine for the heat removal system to technology readiness level (TRL) 5. As an intermediate step, the technology for the turbomachine at the scale of the nuclear power plant (NPP) is validated under experimental conditions in the sCO2-HeRo cycle operated by Kraftwerks-Simulator-Gesellschaft mbH & Gesellschaft für Simulatorschulung mbH (KSG/GfS).

Employing knowledge gained from the experiments in the sCO2-HeRo project, an improved turbomachine for experimental investigation was built following the same concept of an integral design as in sCO2-HeRo. However, the new sCO2-4-NPP turbomachine features active magnetic bearings, which operate in supercritical CO2 (sCO2) and were delivered by subcontractor MECOS AG. The overall layout of the turbomachine is shown in our previously published article.

In February 2021, partners UDE and KSG/GfS together with MECOS AG successfully commissioned the new turbomachine in the sCO2-HeRo cycle. During commissioning, the turbomachine reached a maximum rotational speed of 40 krpm, proving operability in sCO2. Furthermore, the test delivered suitable start and stop strategies to be adopted for the overall heat removal system in the nuclear power plant (NPP) as well as insight into the effect of high density sCO2 on the rotordynamic behaviour of the turbomachine.

Based on the successful commissioning, magnetic bearings are expected to be a valid solution for turbomachines operating with sCO2 and to be applicable for the NPP-scale heat removal system, too.