Innovative sCO2-Based Heat Removal Technology for an Increased Level of Safety of Nuclear Power Plants

Bringing nuclear safety solutions closer to market

The main aim of the sCO2-4-NPP project is to bring an innovative technology based on supercritical CO2 (sCO2) for heat removal in nuclear power plants (NPPs) closer to the market. sCO2-4-NPP builds on results of the previous Horizon 2020 project sCO2-HeRo , where the technology was first developed and brought to experimental proof of concept (TRL3).

The sCO2-4-NPP technology will be a backup cooling system, attached to the principal steam-based cooling system, which will considerably delay or eliminate the need for human intervention (>72 hours) in case of accidents such as station blackouts, thus replying to the need for increased safety in NPPs.

Thanks to the compact size and modularity of the system, it can be retrofitted into existing NPPs and included in future NPPs under development.

Through a close collaboration between major industrial actors and highly-skilled academic institutions, the sCO2-4-NPP partners will bring the full system to TRL5 (technology validated in relevant environment) and parts of it to TRL7 by carrying out experiments, simulations, design, upscaling and validation of the technology in a real NPP Pressurised Water Reactor (PWR) simulator. Regulatory requirements will be considered in the conceptual design of components and the system architecture to increase the chances of acceptance by European nuclear safety authorities and speed up the time to market. Detailed technical, regulatory, financial and marketing roadmaps will be developed for bringing the technology to industrial use (TRL 9) after the project.

The sCO2-4-NPP technology will increase NPP safety, decrease the plant overall environmental footprint, and potentially lower costs for energy consumption, thus increasing the competitiveness of European NPP operators.

How It Works

sCO2 Heat Removal Concept

How does it work?

Project Technical Objectives

How do we do it?

Expected Impact

What are the benefits?

Testing and Simulation

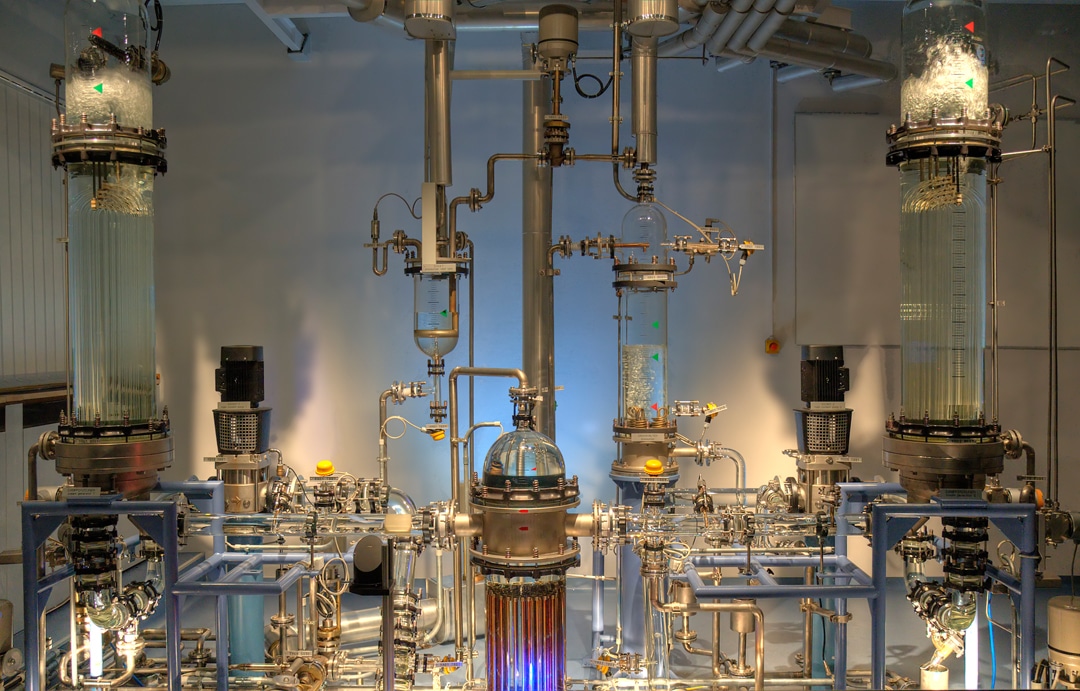

To achieve its objectives the project will use the following test loops:

Reactor glass model at KSG/GfS: The reactor glass model is a reproduction of a two-loop pressurised water reactor (Siemens/KWU design) at a scale of 1:10. It allows the visualisation of operational procedures, incidents and accidents as well as thermal hydraulic effects in a light water reactor. All the phenomena visible in the reactor glass model have occurred in real nuclear power plants.

200 kWth sCO2-HeRo loop: Developed for the sCO2-HeRo project, this loop will provide partners with all the input data necessary to carry out the MW scaling-up. It is currently coupled with the glass model at GfS and is operational.

Training simulator at KSG: The KONVOI simulator is an almost identical replica of a German KONVOI power plant (Konvoi/ pre-Konvoi class of PWR with about 3900 MW thermal power, 1300-400 MW electrical power, 4 loop primary circuit) with respect to the control room.

This implementation will allow partners to test the sCO2 system by simulating its integration in an NPP from a control room operator’s point of view.